Several regions in and across India experience minor to severe earthquakes. Major earthquake incidents involving Killari (1993), Bhuj (2001), and Jammu and Kashmir (2005) have been notable in the past two decades. Severe pressure imposed by seismic shocks threatens construction and might curb further architectural innovations.

To combat natural disasters like earthquakes, India’s iron and steel industry has harnessed advanced technologies to manufacture TMT Bars. Thermo-mechanically treated (TMT) bars render structural strength, ensure longevity and encourage architectural innovation as well.

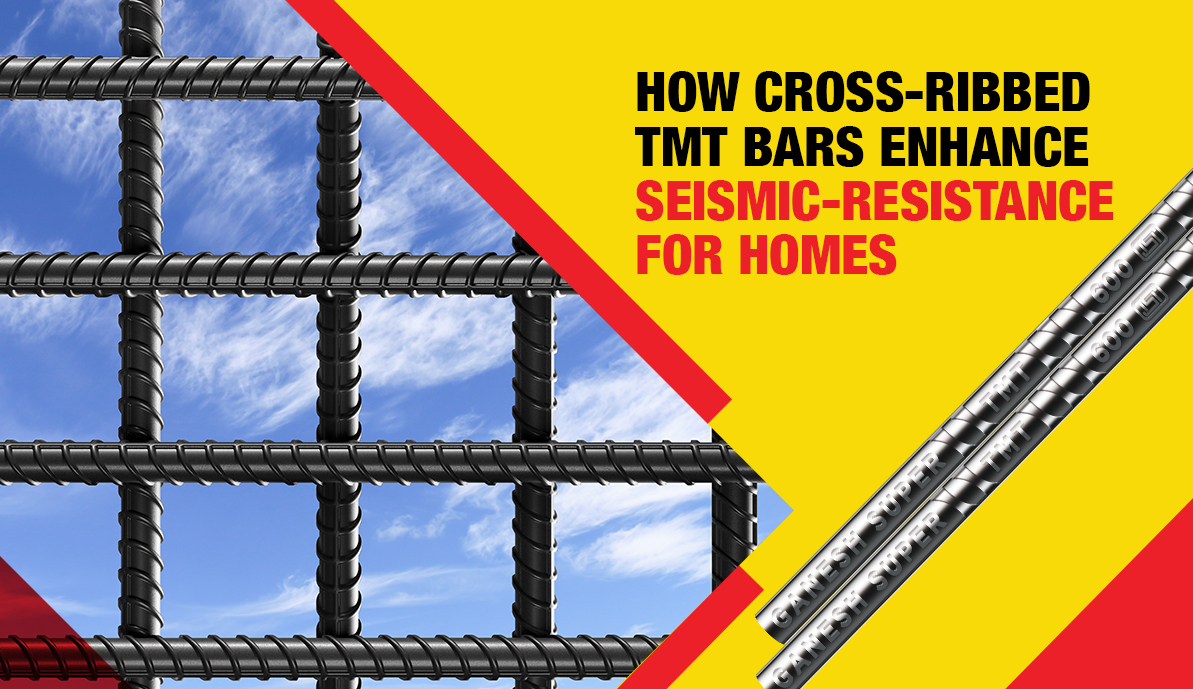

Have you heard about cross-ribbed TMT bars? If you are associated with the construction industry, it is essential to know about cross-ribs. This blog discusses the concept of cross-ribs and why constructions should be them.

Continue reading to know more.

How are Cross-Ribbed TMT different from Regular TMT?

Several renowned TMT bar companies have developed surface designs for their brands, known as Ribs. The ribbed pattern increases the operational efficiency of the TMT bars.

We will involve Thermex Technology in designing the ribs on TMT bars. Our rigorous heat-quenching and water cooling, alongside rolling patterns, have rendered the ribbed patterns. We focus on cross-ribbed patterns, as they offer the highest strength to the structures. As one of the best steel bar manufacturers, we are sure we will provide long-term resilience to your property.

Cross-ribbed TMT bars have more friction and better grip, which prevents slippage. As a result, multi-storeyed buildings are constructed with cross-ribbed TMT bars over regular TMT. So that both architectural flexibility and resilience are equally maintained.

Here’s how they contribute to architectural efficiency.

5 Ways Cross-Ribbed TMT Bars can help

Ductility and Strength

Ductility is a significant feature of TMT bars. As the best TMT Steel Manufacturers, we extensively use self-tempering alongside a constant heating and cooling process. Self-tempering increases the stretchability of our Cross-Ribbed TMT bars, making them suitable for any structure.

Flexibility and Longevity

A building’s structural excellence can often be determined by its longevity. Depreciation, being the mortal enemy, reduces the longevity of your real estate property. Our Cross-Ribbed TMT bars are highly flexible and can be used for diverse structural designs.

We use a protective layer of zinc epoxy coating to prevent the direct exposure of TMT bars to the atmosphere. As a result, an anti-corrosive property is developed, and structures are protected against rust deposition in moisture-prone Indian weather.

Higher Strength

Cross-ribbed TMT bars are more potent than regular TMT bars. Construction companies generally build according to the seismic zones. Similarly, our cross-ribbed TMT bars are manufactured to support all construction endeavours.

For instance, at Ganesh Super, we manufacture cross-ribbed TMT bars in different grades. Our highest grade is 600 EQ-CR, which can dissipate a significant volume of seismic energy and resist structural collapse. As one of the best steel bar manufacturers, we conduct rigorous monitoring for greater performance and resilience.

Earthquake Resistance

Earthquake resistance features are necessary within Cross-Ribbed TMT bars to withstand seismic shocks. Seismic shocks impose high pressure upon building structures, enhancing the risk of collapse.

The cross-ribbed patterns on the bar surface increase its ripping propensity. When the concrete is gripped intensely, the risk of wall cracks automatically decreases. Simultaneously, your buildings’ corrosion index is reduced, and maintenance costs are managed, too.

Energy dissipation is another essential factor present within cross-ribbed TMT bars. The ribbed patterns possess considerable ability to dissipate the kinetic energy of seismic shocks. Once the energy is dissipated, the risks of structural collapse are automatically reduced.

Which TMT Bar is best for Home construction?

Your dream home needs highly resistant and ductile TMT bars. Our cross-ribbed TMT bars of the 600 EQ-CR grade possess the highest strength and support structural innovation. As one of the best steel bar manufacturers, we use advanced manufacturing for our 600 EQ-CR grades.

Here’s why our 600 EQ-CR TMT bars are unique:

- Offers superior weldability, which supports complex structures

- It involves lower carbon content, which reduces emission

- Improved ribbed patterns increase concrete gripping ability

- The presence of microalloying elements reduces brittleness and improves arc stability

- Higher corrosion resistance increases the longevity of constructions.

In Conclusion

When you opt to purchase TMT bars for your construction, it’s best to look into the properties thoroughly. We at Ganesh Super make sure that your buildings, bridges, dams, and factories are adequately supported. Our Cross-Ribbed TMT bars are manufactured with a sole focus on enhanced elasticity, durability, corrosion, and heat resistance. In the future, India’s construction excellence will increase by fostering innovation, efficiency, and resilience.